The importance of underlay

An embroidery design is interaction between the stitches. Each stitch influences the following stitches in terms of stabilization and distortion.

Reasons to Use Underlay

- Underlays are the foundation for the top layer of the embroidery

- They connect fabric and stabilizers

- They give stability to the fabric and prevent distortion

- They prevent that top layer stitches sink into the fabric (especially with high-pile fabrics)

- Underlays also contribute to coverage (enable reduction of cover stitches)

- Underlays add dimension

- Underlays help to clearly define the edges of the top layer and thus increase the quality of the embroidery result

Factors Influencing the Choice of Underlay

- Fabric type (thickness, elasticity, weave type, etc.)

- thin fabric → less underlay

- thick fabric → more underlay

- Stitch type (satin, filling stitches, etc.)

- determines type of underlay

- Stitch density

- low stitch density → less underlay

- high stitch density → more underlay

- longer stitches provide more coverage!

- Shape and size of the pattern

Underlays should be used as consistently as possible in order to produce a uniform look.

Types of Underlays

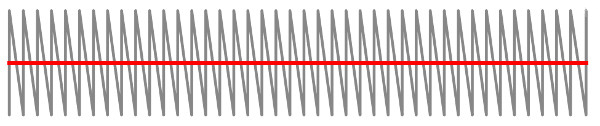

Centerline Underlay

The centerline underlay forms a straight stitch in the middle of a satin column.

It is commonly used for satin columns of 1 mm - 2 mm width.

Depending on the type of fabric, it may be necessary to repeat the centerline underlay 2-3 times to ensure secure top layer placement.

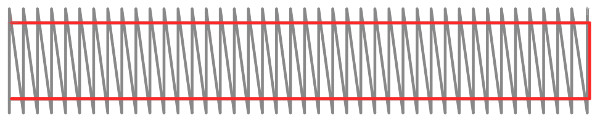

Contour Underlay

The contour underlay runs with a defined indentation along the outer contour of the object.

It is used on satin columns of 2 mm - 3.5 mm width or also for wider satin columns in combination with a zigzag underlay.

The contour underlay serves as a support for the cover stitches and thus plays a special role in the quality of the edges. It should neither be too close to the edge (it could protrude out from the embroidery) nor too far away (the stabilizing function is no longer present). As a basic rule, the inset can be 0.4 mm - 0.6 mm. However, the value can vary depending on the type of fabric.

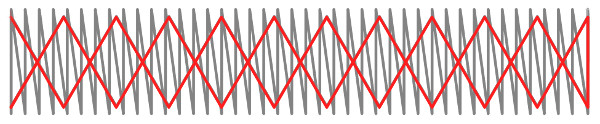

Zig-Zah Underlay

The zigzag underlay is essentially a double satin column with a wide zigzag spacing.

It is usually used in combination with a contour underlay on satin columns wider than 4 mm.

The zigzag underlay adds dimension and lifts the cover stitches from the fabric.

Due to the angle, the stitches of the zigzag underlay are significantly longer than those of the cover stitches. It is therefore recommended to set a value for the maximum stitch length when using a zigzag underlay, even if the actual satin column does not exceed this value. If the stitch length is too long, the zigzag underlay can otherwise have a destabilizing effect.

Fill Underlay

The fill underlay is a filling with wider row spacing, which usually runs perpendicular to the top layer. The stitch length is often also slightly increased. The fill underlay prepares the embroidery surface for the fill and also stabilizes it.

Multiple fill underlays embroidered in different directions are ideal for taming high-pile fabrics and pressing down the fibers.

Manual Underlay

Don’t forget that underlays can also be applied manually. They can be created with running stitches.

- a contour underlay for filling objects which needs clearly defined edges

- lines across the object to stabilize the fabric in the extent of the embroidery area beforehand

- 3D foam requires special underlay stitches to hold the pieces together

- ensure good coverage in areas where two satin columns meet in 90° angle